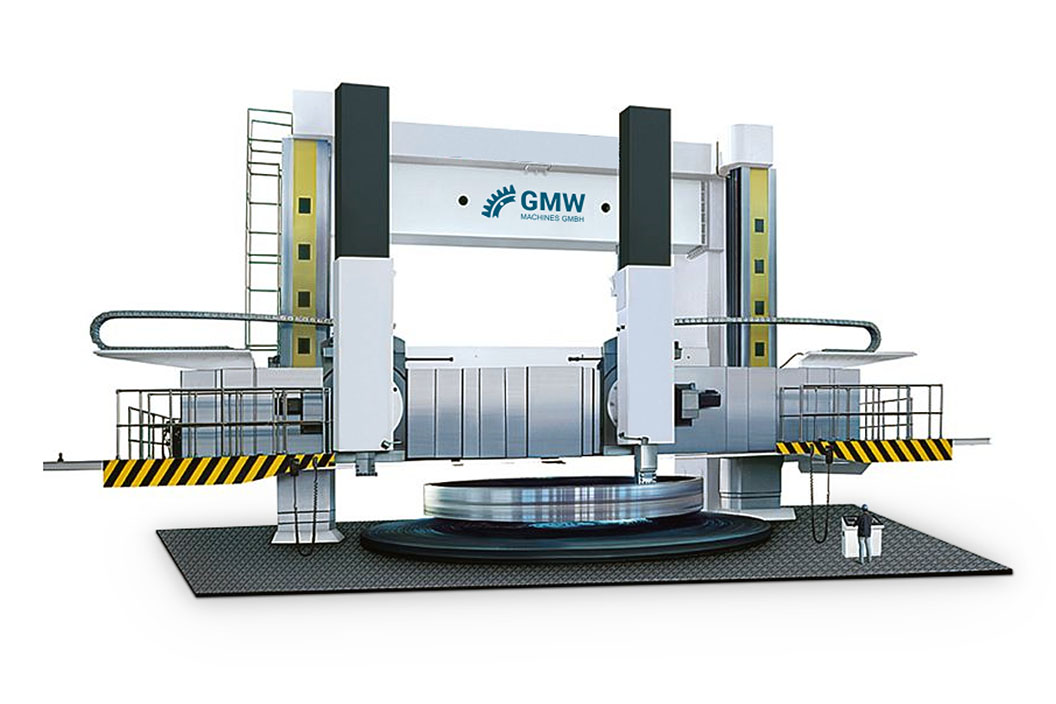

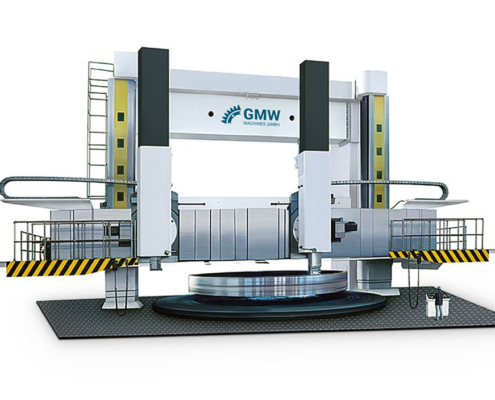

With our CNC double column carousel lathes you acquire an excellent product for turning/milling/drilling/grinding large workpieces. As an experienced supplier, we rely exclusively on established manufacturers and suppliers when assembling our machines. This is reflected in the highest possible quality of our products – but not in the price. Due to our experience and our modular system, with which you only purchase the components you really need, we can offer you this high quality at a fair price.

CNC double column – Machining of large components

These vertical lathes or machining centers enable the user to machine significantly larger components with high precision and efficiency. This is due both to the robust design and technology, which reduces vibrations to a minimum, and to the components we use. We purchase these exclusively from renowned suppliers. Due to our many years of experience, we offer excellent products, so that you receive quality at a low price.

CNC Double Column – Flexible thanks to modular principle

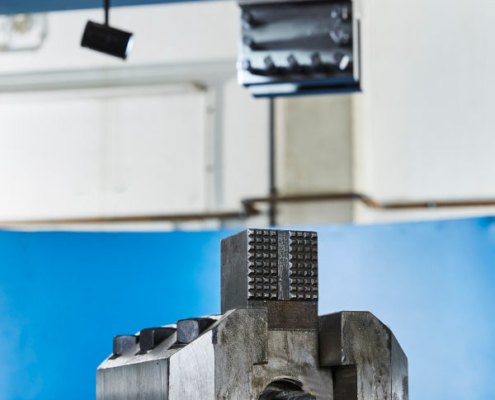

Modern production presents companies with enormous challenges, especially in the areas of speed, flexibility and accuracy. Our CNC double column machines are a good alternative to the machining centre. With our modular system you can adapt them to your individual requirements. Optionally, for example, a C axis for turning/milling/drilling/grinding as well as tailor-made “pickup systems” can be integrated. With these, the set-up times for our machines can be considerably reduced. You can conveniently turn, mill, drill and grind large workpieces.

CNC double column – We use the most modern control system

In order to fully benefit from the high-quality workmanship and flexibility of our CNC double-column vertical lathes, an optimized control system is required. This is why we rely on a powerful CNC control system. We obtain this from Siemens as standard. Should our customers prefer a different supplier, such as Heidenhain or Fanuc, we are naturally happy to integrate their products into our machine.

CNC Double Column – Strong Service

With our CNC double column carousel lathes we sell not only one machine, but a total output. Thus, all our machines naturally comply with the safety requirements of the VDI / VDMA. If you have any questions about our products, we offer you an attractive response time of 48 to 72 hours. In addition, we support you with our in-house GMW service and offer you convenient remote maintenance.

Facts & figures

| Technical data | VTM3150 | VTM3500 | VTM4000 |

|---|---|---|---|

| Max. turning diam. – Ø [mm] | 3150 | 3500 | 4000 |

| Max. turning height [mm] | 2000 | 2000 – 2500 | 2500 – 3200 |

| Table diam. [mm] | 2850 | 3150 | 3600 |

| Weight [t] | 40 | 50 | 63 |

| Speed of work table [Rpm] | 0,63 – 100 | 0,63 – 100 | 0,63 – 100 |

| Speed of work table milling [Rpm] | 0,001 – 1 | 0,001 – 1 | 0,001 – 1 |

| Milling spindle [Rpm] | 10 – 1000 | 10 – 1000 | 10 – 1000 |

| Max. torque of the table [kNm] | 80 | 80 | 80 |

| Max. travel speed of RAM [mm] | 1400 | 1600 | 2000 |

| Milling spindle [kW] | 22 | 22 | 22 |

| Engine power [kW] | 55 | 55 | 55 |

Our machines are delivered with Siemens control as standard. On request, we can also design the machines with Heidenhain and Fanuc controls. The machines are assembled and delivered according to the specifications.

| Technical data | VTM5000 | VTM6300 | VTM8000 |

|---|---|---|---|

| Max. turning diam. – Ø [mm] | 5000 | 6300 | 8000 |

| Max. turning height [mm] | 2500 – 4000 | 3000 – 5000 | 4000 – 5000 |

| Table diam. [mm] | 4500 | 5700 | 7200 |

| Weight [t] | 100 – 160 | 63 – 160 | 100 – 250 |

| Speed of work table [Rpm] | 0,6 – 80 | 0,3 – 50 | 0,2 – 30 |

| Speed of work table milling [Rpm] | 0,001 – 1 | 0,001 – 1 | 0,001 – 1 |

| Milling spindle [Rpm] | 10 – 1000 | 10 – 1000 | 10 – 1000 |

| Max. torque of the table [kNm] | 125 | 160 – 400 | 315 – 530 |

| max. travel speed of RAM [mm] | 2500 | 2500 | 3150 |

| Milling spindle [kW] | 22 | 28 | 28 |

| Engine power [kW] | 55 | 55 – 81 | 81 – 125 |

Our machines are delivered with Siemens control as standard. On request, we can also design the machines with Heidenhain and Fanuc controls. The machines are assembled and delivered according to the specifications.

| Technical data | VTM10000 | VTM12500 | up to VTM28000 |

|---|---|---|---|

| Max. turning diam. – Ø [mm] | 10000 | 12500 | up to 28000 |

| Max. turning height [mm] | 4000 – 6500 | 5000 – 6500 | 12000 |

| Table diam. [mm] | 8000 | 10000 | 12000 |

| Weight [t] | 250 – 400 | 250 – 500 | 800 |

| Speed of work table [Rpm] | 0,2 – 25 | 0,2 – 25 | 0,1 – 12 |

| Speed of work table nilling [Rpm] | 0,001 – 1 | 0,001 – 1 | – |

| Milling spindle [Rpm] | 10 – 1000 | 10 – 1000 | – |

| Max. torque of the table [kNm] | 500 – 630 | 630 – 750 | 1000 |

| Max. travel speed of RAM [mm] | 3250 | 3250 | 5000 |

| Milling spindle [kW] | 39 | 39 | – |

| Engine power [kW] | 143 | 143 | 200 |

Our machines are delivered with Siemens control as standard. On request, we can also design the machines with Heidenhain and Fanuc controls. The machines are assembled and delivered according to the specifications.