Product description

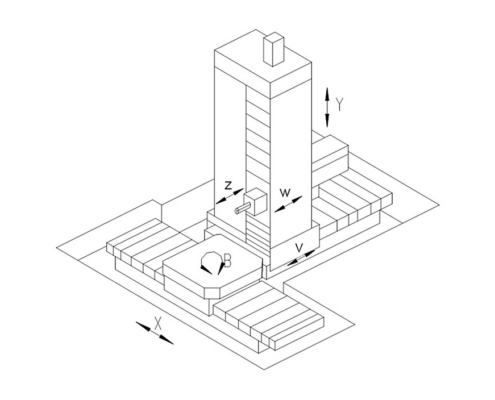

GMW boring mills are designed for the heaviest machining operations on large workpieces. The interaction of high-quality mechanical (casting) and control components guarantees high efficiency and accuracy in drilling and milling, turning and grinding.

Depending on the customer’s requirements and the field of application, the plate boring mills can be extended by the following modules:

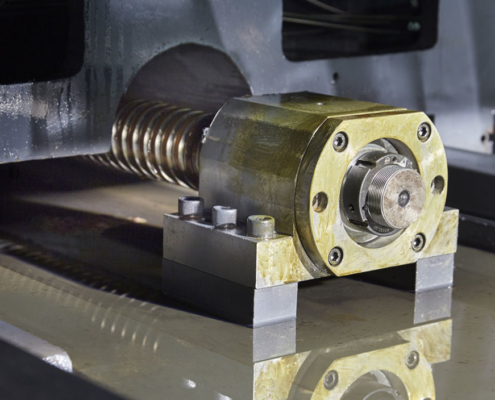

- Support sleeve spindles

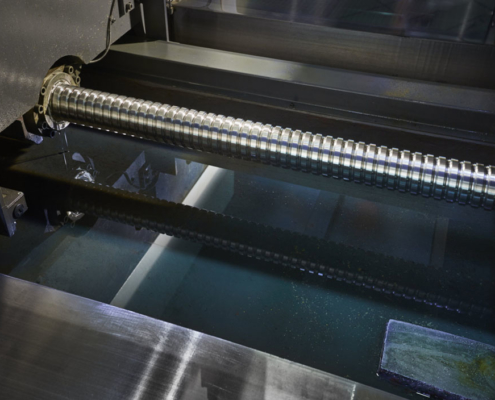

- Hydrostatic or linear guides

- Controls from Heidenhain, Siemens or Fanuc

- Tool changer

- Cross slide

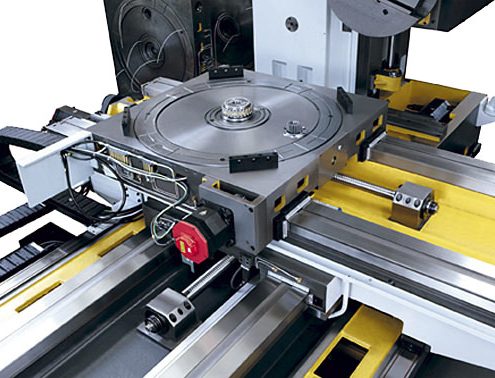

- Rotary tables

- Clamping plates

This increases the work contents per fixture. Through our network of technology partners, it is also possible to respond to the wishes of our customers with custom-made products.

Facts & figures

| Technical Data | FB130CNC | FB160CNC | FB160CNC (linear) | FB200CNC | FB225CNC |

|---|---|---|---|---|---|

| Spindle diam. [mm] | 130 | 160 | 160 | 200 | 225 |

| Milling spindle diam. [mm] | 221 | 260 | 260 | 300 | 380 |

| Spindle taper | ISO 50 | ISO 50 | ISO 50 | ISO 60 | ISO 60 |

| Spindle speed [Rpm] | 2 – 2.500 | 2 – 2.500 | 10 – 2000 | 2 – 2.000 | 2 – 2.000 |

| Power of spindle motor [kW] | 37 | 51 | 51 | 60 | 71 |

| Max. torque of boring spindle [N.m] | 2.500 | 5.000 | 2.500 | 6.000 | 7.000 |

| Max. axial resistance of boring spindle [N] | 25.000 | 50.000 | 25.000 | 55.000 | 60.000 |

| Max. torque of milling spindle [N.m] | 3.150 | 11.000 | 2.600 | 12.000 | 15.000 |

| Ram size (W/L) [mm] | 420 x 480 | 481 x 580 | 450 x 450 | 481 x 580 | 580 x 700 |

| Cross travel of column X-axis [mm] | 6.000 | 8.000 | 6.000 | 10.000 | 12.000 |

| Vertical travel of spindle Head Y-Axis [mm] | 2.000 | 3.000 | 3.000 | 4.000 | 5.000 |

| Axial travel to run Z-axis [mm] | 800 | 1.100 | 1.000 | 1.200 | 1.250 |

| Travel to spindle W-axis [mm] | 800 | 900 | 800 | 1.200 | 1.250 |

| Feed rate X-axis [mm/min] | 2 ~ 8000 | 1 – 8000 | 1 ~ 8000 | 1 ~ 8000 | 1 ~ 8000 |

| Feed rate Y-axis [m/min] | 2 ~ 8000 | 1 – 6000 | 1-8000 | 1 – 6000 | 1 – 6000 |

| Feed rate Z-axis [mm/min] | 1 – 4.000 | 1 – 8.000 | 1 – 4000 | 1 – 4000 | |

| Feed rate W-axis [mm/min] | 2 – 6.000 | 1 – 4.000 | 1 – 8.000 | 1 – 4000 | 1 – 4000 |

| Rapid Feed X-axis [mm/min] | 8.000 | 6.000 | 12.000 | 8.000 | 8.000 |

| Rapid Feed Y-axis [mm/min] | 8.000 | 6.000 | 12.000 | 6.000 | 6.000 |

| Rapid Feed Z-axis [mm/min] | 6.000 | 4.000 | 12.000 | 4.000 | 4.000 |

| Rapid Feed W-axis [mm/min] | 6.000 | 4.000 | 12.000 | 4.000 | 4.000 |

| Total Power [kVA] | 125 | no | 145 | 120 | 140 |

| Overall dimensions [mm] | 10.720 x 4.000 x 4.970 | 14.566 x 7.155 x 7.401 | 12.550 x 3.800 x 4.1520 | 15.566 x 7.455 x 8.401 | 19.166 x 7.655 x 9.485 |

| Machine weight [t] | 65 | 113 | 58 | 128 | 168 |

Our machines are delivered with Siemens control as standard. On request, we can also design the machines with Heidenhain and Fanuc controls. The machines are assembled and delivered according to the specifications.

| Table Size (W x L) [mm] | 1.800 x 2.000 2.000 x 2.000 2.000 x 2.500 | 2.000 x 2.000 2.000 x 2.500 | 2.500 x 2.500 2.500 x 3.000 3.000 x 3.000 | 3.000 x 3.000 3.000 x 3.500 3.000 x 4.000 | 4.000 x 4.000 4.000 x 4.500 4.000 x 5.000 |

|---|---|---|---|---|---|

| Max. table loading [t] | 20 | 30 | 40 | 60 | 100 |

| Table Height [mm] | 1150 | 1300 | 1380 | 1605 | 1650 |

| T-slot size [mm] | 28 | 28 | 28 | 28 | 28 |

| Linear motion travel [mm] | 2000 | 2000 | 2000 | 2000 | 2000 |

| Table rotation angle [°] | 360° | 360° | 360° | 360° | 360° |

| Feed Range V-axis [mm/min] | 1 – 4000 | 1 – 4000 | 1 – 4000 | 1 – 4000 | 1 – 4000 |

| Feed Range B-axis [mm/min] | 0.003 – 1 | 0.003 – 1 | 0.003 – 1 | 0.003 – 1 | 0.003 – 1 |

| Rapid Feed V-axis [mm/min] | 4000 | 4000 | 4000 | 4000 | 4000 |

| Rapid Feed B-axis [mm/min] | 1,00 | 1,00 | 1,00 | 1,00 | 1,00 |

| Positioning Accuracy V-axis [mm] | 0,02 | 0,02 | 0,02 | 0,02 | 0,02 |

| Positioning Accuracy B-axis [mm] | 10″ | 10″ | 10″ | 10″ | 10″ |

| Repeatability V-axis [mm] | 0,015 | 0,015 | 0,015 | 0,015 | 0,015 |

| Repeatability B-axis [“] | 6″ | 6″ | 6″ | 6″ | 6″ |

Our machines are delivered with Siemens control as standard. On request, we can also design the machines with Heidenhain and Fanuc controls. The machines are assembled and delivered according to the specifications.