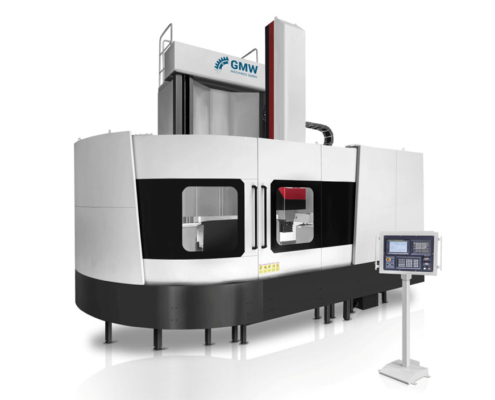

The compact GMW single-column vertical turning lathes are suitable for turning smaller workpieces. These single-column vertical lathes are particularly characterised by their solid and efficient design, as well as their unique price/performance ratio.

The rigid cast construction of the Single-Column Lathe ensures low-vibration and precise machining; hydrostatic guides also dampen the vibrations.

Single Column – What distinguishes our machines

Our CNC single columns captivate by highest quality. This starts with the compact and solid construction. This results in a long service life for the lathes. But our products are also convincing in terms of precision. Since we rely exclusively on brand manufacturers for components such as bearings, motion spindles, electronics, hydraulics and pneumatics, the hardware is convincing all along the line. In addition, the solid or robust cast construction of the vertical lathes enables low-vibration and precise machining of workpieces. In addition, the hydrostatic guide dampens any vibrations that occur during machining to a minimum.

- Datenblatt (PDF)

- Katalog(PDF)

- Video VMT16000CNC (PDF)

- Video VMT28000CNC (PDF)

CNC single column – Versatile application thanks to modular principle

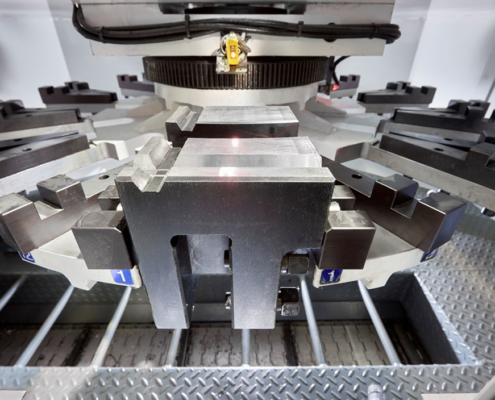

Our CNC single columns stand for flexibility and quality thanks to our modular principle. In addition to the standard versions, you have the option of equipping the lathes according to your requirements. For example, depending on the machine design, multiple machining for drilling / milling / grinding of workpieces is also possible. Thanks to our experience and cooperation with an established network of technology partners, we are also able to implement special designs on customer request. Please do not hesitate to contact us.

- Datenblatt (PDF)

- Katalog(PDF)

- Video VMT16000CNC (PDF)

- Video VMT28000CNC (PDF)

CNC single column – Modern control system

The computer-aided control of our CNC single-column vertical lathes offers numerous advantages compared to conventional production. Even with a low workpiece weight, users can achieve absolutely exact results during production thanks to the precise CNC control. We deliver our machines with Siemens control as standard. If desired, you can also have a controller from another supplier such as Heidenhain or Fanuc installed in your machine.

- Datenblatt (PDF)

- Katalog(PDF)

- Video VMT16000CNC (PDF)

- Video VMT28000CNC (PDF)

CNC Single Column – Our Service

Our CNC columns, like all our other machines, comply with the safety requirements of the VDI / VDMA. In addition, we advise you in detail on all questions that arise about our products and guarantee a response time of 48 to 72 hours. We are also at your side after the purchase of a machine with our in-house GMW service. The possibility of convenient remote maintenance rounds off our services.

- Datenblatt (PDF)

- Katalog(PDF)

- Video VMT16000CNC (PDF)

- Video VMT28000CNC (PDF)

Facts & figures

| Technical data | SVTM1200CNC | SVTM1600CNC | SVTM2000CNC | SVTM2500CNC |

|---|---|---|---|---|

| Turning Diam. – Ø [mm] | 1.250 | 1.600 | 2.000 | 2.500 |

| Ø – Table diam. [mm] | 1.050 | 1.400 | 1.600 | 2.000 |

| Turning height [mm] | 1.000 | 1.600 | 1.400 | 2.000 |

| Table load [t] | 5 | 8 | 12 | 16 |

| Table speed [Upm] | 4 – 400 | 3.15 – 315 | 2.5 – 250 | 2 – 200 |

| Table speed milling [Rpm] | 0,001 – 1 | 0,001 – 1 | 0,001 – 1 | 0,001 – 1 |

| Milling spindle [Rpm] | 10 – 1000 | 10 – 1000 | 10 – 1000 | 10 – 1000 |

| Torque at Table [kNm] | 10 | 20 | 25 | 32 |

| RAM travel (horizontal) [mm] | 1000 | 1.400 | 1.400 | 1.600 |

| RAM Travel (vertical) [mm] | 870 | 1200 | 1400 | 1400 |

| RAM speed max. [mm/min] | 6.000 | 6.000 | 6.000 | 6.000 |

| Crossbeam travel [mm] | 500 | 1000 | 1000 | 1400 |

| Crossbeam speed [mm/min] | 300 | 300 | 300 | 300 |

| Motor power [kW] | 37 | 55 | 55 | 55 |

| Total weight [t] | 12 | 23 | 26 | 31 |

| Required space [m] | 4,7 x 5.5 x 4,5 | 4.8 x 6.2 x 5.6 | 5.4 x 6.2 x 5.6 | 6,4 x 6.8 x 6,0 |

Our machines are delivered with Siemens control as standard. On request, we can also design the machines with Heidenhain and Fanuc controls. The machines are assembled and delivered according to the specifications.